I had this iPhone 12 Pro Max come in for Data Recovery.

It had corrosion near the power button connector, but it actually wasn't that bad.

The device booted, but it was in recovery mode. I would exit recovery mode with 3u tools but would still go back to recovery mode.

This made no sense. Why would water damage do this?

So I flashed an update & it went through successfully, 100% with no errors, but once again, it booted back to recovery mode.

This led me to think...

There was water damage near power button connector

12PM will go into recovery mode if the power button connector is pressed down all the time while booting

Maybe it has to do with the power button connector.

So I booted up the phone & measured the power button pin's voltage. It was like 0.6V.

If you know how power button lines work, they actually have a HIGH signal (1.8V in this case), and when that signal goes LOW (0V), that's how the device is told electrically, to process the power button being pressed function.

Therefore, if the voltage at the connector is stuck at 0.6V (essentially NOT 1.8V as it should be), that means the phone thinks the power button connector is being pressed down.

But it's not pressed down by anyone. it's shorted or failed where it can't be in a state where it has a HIGH signal.

So now it all made sense. The power button line (IO_BUTTON_SIDE_L_1V8) was bad.

Checking the schematics & ZXW, you can see that line basically is generated by the PMIC.

At this point, I have 2 options:

1. I replace PMIC & hope that solves it - it probably would. But that required splitting the sandwich & doing PMIC, which is super risky

2. Or... I feed it 1.8V from somewhere else & hope the voltage from the other 1.8v power source doesn't get pulled down by the short in the PMIC.

The first thing I tried was, jumping PP1V8_ALWAYS to IO_BUTTON_SIDE_L_1V8

Buuuut, then the device wouldn't boot anymore. It would hang at 20mA after prompt to boot.

At this point, I asked some friends about this issue. Sure enough, Aaron Harrington said he had a video on this exact issue, which i'll link in the comments.

Basically, I needed to check the volume button lines as well, which sure enough, were also in a LOW state.

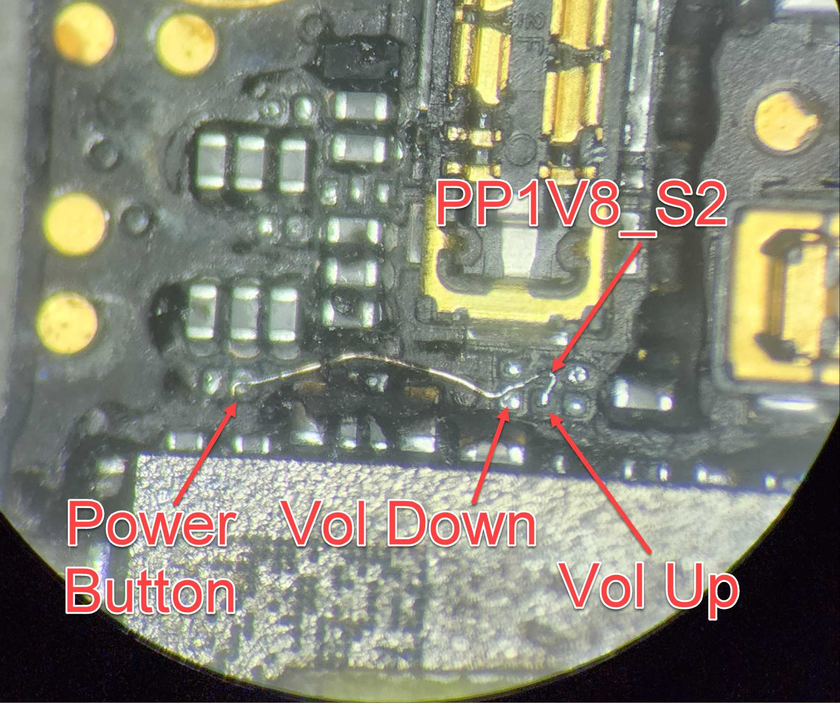

In his video, he jumped PP1V8_S2, which is in that same general area, to the Vol up, Vol down.

Then he jumped PP1v8_Always to power button line.

Not sure why it worked for him, but not me.

So I just decided to jump all 3 lines to PP1V8_S2

And BOOM, it booted! And I got the data! 🙌

So let me know.. what did you learn from this post? Let me know down below 🤔

If you have a Seek Thermal Cam, you're missing out if you don't have a VCC Seek Stand: https://www.vccboardrepairs.com/buy-seek-stand

Injured Gadgets just got these back in stock, so get them while you can!

It can take us a while to build these out sometimes, so they're sometimes out of stock for a while, but we're working towards always having inventory ready to build more as they sell out.

This stand makes using a thermal cam so easy. So much better than any other thermal solution on the market.

It allows you to get real close up (using my Macro Lens), and easily find where the short is coming from.

Plus it's hard free, so you can have your hands free to try to boot the device from DCPS, while having an image that is in focus & not moving around.

You can even record a video through the app, while you inject voltage into the short, so you can go back & see exactly which component was it that was heating up.

Save yourself lots of time by getting a Seek Cam, Stand & Macro Lens! ...

Anyone who is doing game console repairs, knows how many screws you need to remove to access the motherboard.

Especially the PS5, with the 5,000 screws or so.

If you don't already have an electric screwdriver, GET ONE ASAP.

🌟 Cordless Screwdriver with T9 Bit: https://amzn.to/3E5duCj

🌟Extended T9 Bit: https://amzn.to/3c4YJac

It's rechargeable through micro USB and allows you to easily swap the tips out. You can also fold it to be straight or L shape.

Let me know below if you are already using an electric screwdriver 👇👇

This iPad Pro 11-inch had already been worked on, but the real problem wasn’t the port.

Using a USB-C PD meter and Mechanic USB-C tester, I was able to confirm abnormal charging behavior and trace the issue deeper into the board. The fault ended up being a failed CD3215C00 charging controller IC and TriStar.

After replacing the ICs, recovering the battery voltage, and verifying proper USB-C PD negotiation, the iPad returned to full 15V fast charging.

This is why proper diagnostics matter. The charging port is only one part of the circuit.

—

Repair techs: how often do you see charging IC failures after port damage?

—

Watch the full repair video here 👀:

Just posted a new iPad charging port repair video for techs dealing with base model iPads and Air/Pro variants with soldered dock flexes.

This iPad 7 was a classic life but no charge case. In the video I walk through:

- Confirming it’s a charging issue and not a no-power board fault

- Using a USB charging meter to verify current draw

- Verifying the port with the Mechanic Lightning tester

- Confirming dock flex failure with the Blue Tristar tester

- The soldering technique I use to remove and replace these dock flexes without ripping pads or damaging surrounding components

This design applies to multiple iPad generations, so the diagnostic and soldering process carries over to a lot of models.

Curious who still struggles with replacing these dock flexes without ripping pads?

🔥Full video breakdown of diagnosing and replacing a soldered iPad charging port:

Device came in water damaged after a previous repair attempt by another technician.

Board had scraped areas near the battery connector, unnecessary UV mask around multiple components, and incomplete inspection (main CPU shield was never removed).

Initial checks:

VPH power and VBAT lines not shorted

1V8 rail was hard shorted

Troubleshooting process:

Removed shields that were never taken off during the previous attempt

Removed charging IC due to questionable solder work

Removed a nearby IC that was still corroded underneath

Used DCPS + thermal camera to inject voltage and attempt to locate the short

Continued inspection and testing until no further progress could be made

At that point, proceeded with a full CPU swap:

CPU, RAM, UFS, and EEPROM transplanted to a known good board

Device booted and data was successfully recovered.

Full breakdown is up on YouTube. Link in the comments below